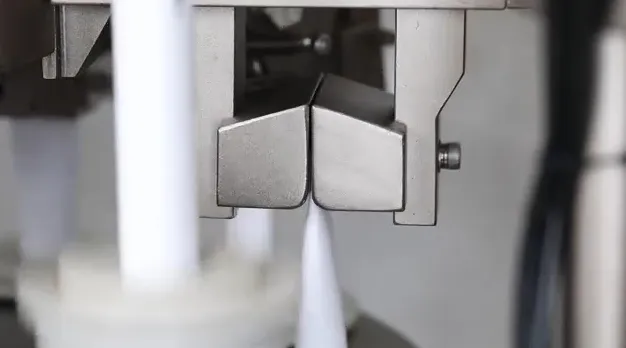

The automatic aluminum tube filling and sealing machine is designed for manufacturing processes in cosmetics and ointment products. This ointment filling machine automates tube feeding, orientation, heating, sealing, and pre-treatment, utilizing a mechanical piston filling system with advanced electrical and control systems. It is ideal for industries such as pharmaceuticals, food, and personal care products.

Filling various personal care products and shoe care products

| Model | NF-60Z |

| Production Capacity | 30-50 tubes/min |

| Filling Range | 5-250 ml/tube |

| Filling Accuracy | ≤±1% |

| Room Temperature | 18-26℃ |

| Motor Power | 1.1kW |

| Machine Dimensions (L×W×H) | 1950×1000×1800mm |

| Machine Weight | 850kg |

| Working Pressure | 0.5-0.7MPa |

| Power Supply | 3 phase, 4 wire AC |

| Voltage | 380V |

| Frequency | 50Hz |

| Current | 25-30Hz |

| Diameter of Aluminum Tube | 13-35mm |

| Max. Length of Aluminum Tube | 180mm (including cap) |

| Air Consumption | 1.1m³/min |

| Noise Level | <75dB |

| Voltage Variation | ±10% |

| Heat Insulation Barrel | 2kW (optional) |

| Mixing Power | 0.18kW (optional) |

Let us help bring your projects to life by answering your questions and providing tailored solutions. Reach out to us anytime.

SINOPED specializes in the research, development, production, and sales of the pharmaceutical manufacturing equipment, including packaging machinery, mixing systems, filling equipment, API manufacturing machinery, and cleanroom solutions. Our comprehensive product range is widely applied in industries such as pharmaceuticals, biopharmaceuticals, and health supplements, supporting efficient and reliable production processes.